|

Today most architects and design professionals are moving away from traditional materials like carpet, tile, pavers and vinyl. Instead, they prefer to specify terrazzo, polished concrete or resinous floor and wall systems. Cost, durability, safety and unlimited design options are just a few of their desirable qualities. |

|

Dyed and polished concrete flooring has been steadily changing the commercial and residential markets. This surface is perfect for custom logos, colorful graphics and unique designs to create a distinctive look for interior and exterior environments. You can transform a damaged concrete floor or use its polished look to add life to an existing one. The result will be durable and beautiful. |

The Standard at Knoxville

US Coast Guard Auxiliary

Residence

University of North Florida |

Advantages • Low maintenance |

|

Resinous systems for floors and walls have actually been around for a long time. They consist of four primary systems as described below. The components of each system are matched specifically to the uses and challenges of a space.Resinous systems offer a smooth, uniform and non-porous surface with great aesthetics. This makes them extremely versatile and ideal for schools, hospitals, airports, restaurants, retail stores and homes. Many institutional and “clean” manufacturing facilities use resinous surfaces for walls because they can withstand wash-downs and frequent impacts. With the increased awareness of environmental safety, new technologies now offer no or low odor products, greater longevity and lower life cycle costs. THE RIGHT SYSTEM MATTERS and we’ll help you determine what’s right for your space. |

|

1. Decorative Resinous Products provide a multi-colored finish using colored aggregates such as quartz, plastic, glass or vinyl chips which are embedded in the surface. Its strength, durability and decorative finish are great for institutional facilities, laboratories, restrooms, locker rooms, food service or light to medium production facilities. |

Netpark |

Advantages • Low maintenance |

|

2. MMA (Methyl Methacrylate) is an acrylic resin available in a broad range of colors. It can resist cracking and is perfect for chemical processing areas, food processing, freezers and refrigerated facilities. MMA is particularly useful when you need a quick installation to reduce downtime and production shut downs. Also, its superior UV stability and non-slip surface make it ideal for pool decks, patios and walkways. Homeowners frequently choose it for garages. |

Veterinary Emergency Center |

Advantages • Low maintenance |

|

3. Urethane Mortar produces a dense, non-porous surface that is chemical and dirt resistant. It can also withstand high heat temperatures. This system is well suited for medium to heavy duty traffic areas such as commercial food service. Colored aggregates can be easily added to give your floor a decorative finish. |

PDQ Restaurant |

Advantages • Low maintenance |

|

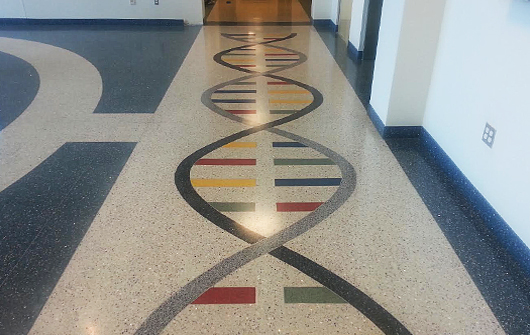

4. Terrazzo is a composite material used for floor and wall surfaces that are poured in place or precast. Typically it consists of marble, quartz, granite and glass chips and poured with a cement binder. It is then cured, ground, and polished to a smooth surface. Terrazzo is most common in high-stress and high-traffic areas such as schools, homes, airports and office buildings. |

Indian River State College

Valencia College

University of South Florida

St. Lucie County Court of Clerks

Collier County Courthouse

Embraer Executive Aircraft |

Advantages • Long lasting |

COATING OPTIONS AVAILABLEChemical resistant coatings are designed for maximum resistance to environmental and industrial chemicals and help keep your facility, employees and community safer. They are often used in commercial kitchens and laboratories, food production facilities and manufacturing plants. ESD (Electrostatic Dissipative) coatings are highly desired for places where static-sensitive equipment is frequently used or where a static-free environment is essential. They are ideal for clean rooms, laboratories, hospitals and manufacturing facilities or where volatile compounds, explosive dust or flammable vapors are present. Non-slip coatings can stop accidents before they happen. Due to its abrasive peaks and valleys, they are extremely popular in food processing areas. Schools and community centers often use them in locker rooms for added safety. Thermal resistant coatings are designed to withstand extreme temperatures and thermal shock, commonly found in many manufacturing processes, commercial kitchens and food processing. Waterproof coatings provide topside protection for concrete surfaces. This seamless watertight surface is perfect for floors and walls alike. It is also a popular safeguard for exterior pool decks and walkways. Vapor control coatings offer protection against moisture vapor. They can significantly reduce the loss of adhesion, warping, peeling, bubbling or poor appearance of moisture-sensitive materials. |